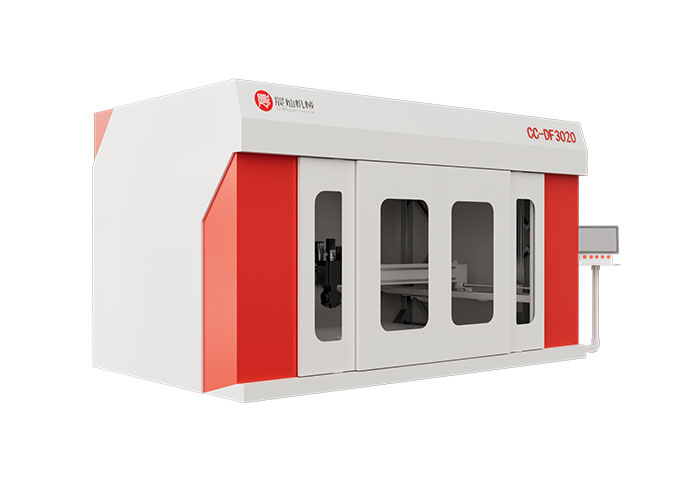

2014

Committed to replacing imported equipment in the field of large-scale composite material machining, CHENcan Machinery launched its R&D project in 2012 and, by 2014, successfully developed the first 5 axis cn machining center for composites with RTCP (Rotating Tool Center Point) functionality among private enterprises in mainland China. The bi-rotary head technology was also independently developed in-house.

In addition, CHENcan was among the first in the industry to adopt advanced installation and calibration tools such as laser interferometers — further enhancing equipment precision and reliability, and setting a new benchmark for domestic high-end composite machining technology.